Technology ferries imagination closer to reality, the best example to reinstate this is, how 3d printing services auburn CA has changed the presentation world of architecture designs. It's like pulling out the multi-dimensional images from your brain and painting them on a paper to see how it looks.

The impact 3D modeling has on presenting architectural services is undoubtedly the most transforming thing to have happened. Let's take an account of the architecture presentation benefits because of 3D modeling.

- Realistic, easy, and

quick

From deducing the scores of horizontal, vertical and diagonal lines of the 2D sketches to getting a one-shot picture of the architectural services is what 3d printing services auburn CA Your design becomes more vivid and your clients can take a virtual tour of their construction projects. You can also quickly check whether a new plan is viable or check how small changes to the design would look like.

- Better for marketing and

project approvals

The experience of going through a 3D model is more compelling and satisfying to a prospect than viewing a 2D drawing. The vivid imagery lingers in the prospect's mind for a longer period of time and you stand a better chance of winning the customer. Similarly the project approval rate in construction business is quicker when a 3D model is used.

- Easy remodeling and

corrections

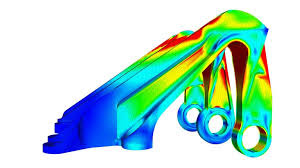

In a 3D model it is easier to see the impact on the overall design when minor or major changes are made, this would help in finalizing the design without much cost and post-construction cost-incurring changes or corrections. It is also accurate as the end construction shapes-up to the conceived output as deduced from the 3D model.

- Impact on project

execution

With a clear design it is easier for the construction engineers to complete the project at low costs and as per the plan.

A report presented by Sheryl Staub and Atul khanzode found that these technologies had a dramatic impact on project execution, including - - Elimination of field interferences

- Less rework

- Increased productivity

- Fewer requests for information

- Fewer change orders

- Less cost growth

- A decrease in time from start of construction to facility turnover.

- Boon for interior

designers

You can design a life-like model of a residential or commercial flat with all the furniture, wall paints and designs, show pieces, designer ceiling and so on to give your clients a compelling view of their dream home or office building.

- Measurements

A 3d printing services auburn CA can clearly show the physical dimensions of the objects and its distance in relation with other objects in the total layout. This will tremendously help customers see and adjust arrangements of objects based on their sizes to achieve varied objectives like space, movement problems, room size corrections, and so on.

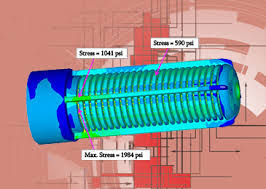

Various research studies have documented the benefits of applying 3D/4D tools specifically to the coordination of Mechanical, Electrical, Plumbing, and Fire Protection (MEP/FP) systems on complex projects (e.g., Khanzode et al., 2005, Staub-French and Fischer 2001).

- Fewer instructions and no

language barriers

Unlike 2D designs which may need clear instructions on how to deduce design information, 3d printing services auburn CA are almost instruction-less and without any language barriers. It is natural for any human to understand 3D design and experience the virtual reality it creates.